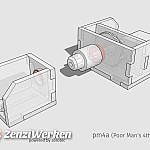

PoorMans4thAxis

This build was done on a desktop cnc-machine by Stepcraft from 6.5 mm birch plywood and some 5 mm Pertinax using a 1.2 mm spiral toothed flute. Furthermore, I used

- 2 Ballbearings Type 6000ZZ (10 x 26 x 8 mm)

- 1 Ballbearing Type 608ZZ (8 x 22 x 7 mm)

- small chuck (10 mm 3/8'' x 24 UNF) with SDS-Plus-adapter

- NEMA17 stepper

- a sharpened M8 machine screw and a self-locking nut (for the tailstock)

- some M3 machine screws

The two gears have a pretty uncommon cycloidal (round) teeth, which helped me to create smaller teeth because they don't have any corners. Otherwise, the teeth size would have been limited by the diameter of my milling bit.

The motor is driven by plugging it into the X-axis stepper driver. This way the machine won't move sideways, but instead, the workpiece does. The distance of travel for one revolution is calculated depending on the diameter of the workpiece divided by the gear reduction of 6 : 1. For example, my tires have 40 mm diameter. So the circumference is 40 mm x π (3.1415) = 125.66 mm / 6 = 20.94 mm. I entered this value in the controller settings.

When using the pm4a it'd be a good idea to use some kind of cover to prevent dust from getting into the gearing.

Download at Thingiverse buy me a coffee commercial license?